WSSC Water staff invents Swiss army knife of hydrant repair tools

November 16, 2022

AWWA Articles

WSSC Water staff invents Swiss army knife of hydrant repair tools

An internally-developed tool to simplify the maintenance and repair of fire hydrants is helping WSSC Water improve safety and efficiency while reducing costs. Recently, the Universal Fire Hydrant Tool received a patent from the U.S. Patent Office.

The tool replaces many previously needed by WSSC Water crews to repair five different types of hydrants included in a network of 42,000 hydrants throughout the Maryland utility’s 1,000-square-mile distribution system. Using the tool, crews can simply remove the old assembly inside a hydrant and replace it with a new one without digging, resulting in a significant cost savings and a reduction in time that the hydrant is out of service. (Pictured above, WSSC’s Terry Hartle demonstrates the fire hydrant tool.)

The tool replaces many previously needed by WSSC Water crews to repair five different types of hydrants included in a network of 42,000 hydrants throughout the Maryland utility’s 1,000-square-mile distribution system. Using the tool, crews can simply remove the old assembly inside a hydrant and replace it with a new one without digging, resulting in a significant cost savings and a reduction in time that the hydrant is out of service. (Pictured above, WSSC’s Terry Hartle demonstrates the fire hydrant tool.)

“Fire hydrants are crucial to protecting public health and safety,” said WSSC Water General Manager and CEO Carla Reid. “This one tool will allow our crews to more quickly and efficiently make repairs to hydrants – safeguarding our customers and saving money. The Universal Fire Hydrant Tool and this patent represent our commitment to fostering and maintaining an innovative, can-do culture here at WSSC Water.”

WSSC Water’s development of a more efficient process to repair hydrants began in 2019, when utility technician Terry Hartle noted that crews needed to carry 10 to 15 tools per hydrant in their trucks to be sure they could repair any of the hydrants in WSSC Water’s service area.

To simplify the process, James Haldeman, a principal engineer from WSSC Water’s Strategy and Innovation Office, worked with field technicians and the utility’s trade shop to design the Universal Fire Hydrant Tool.

To simplify the process, James Haldeman, a principal engineer from WSSC Water’s Strategy and Innovation Office, worked with field technicians and the utility’s trade shop to design the Universal Fire Hydrant Tool.

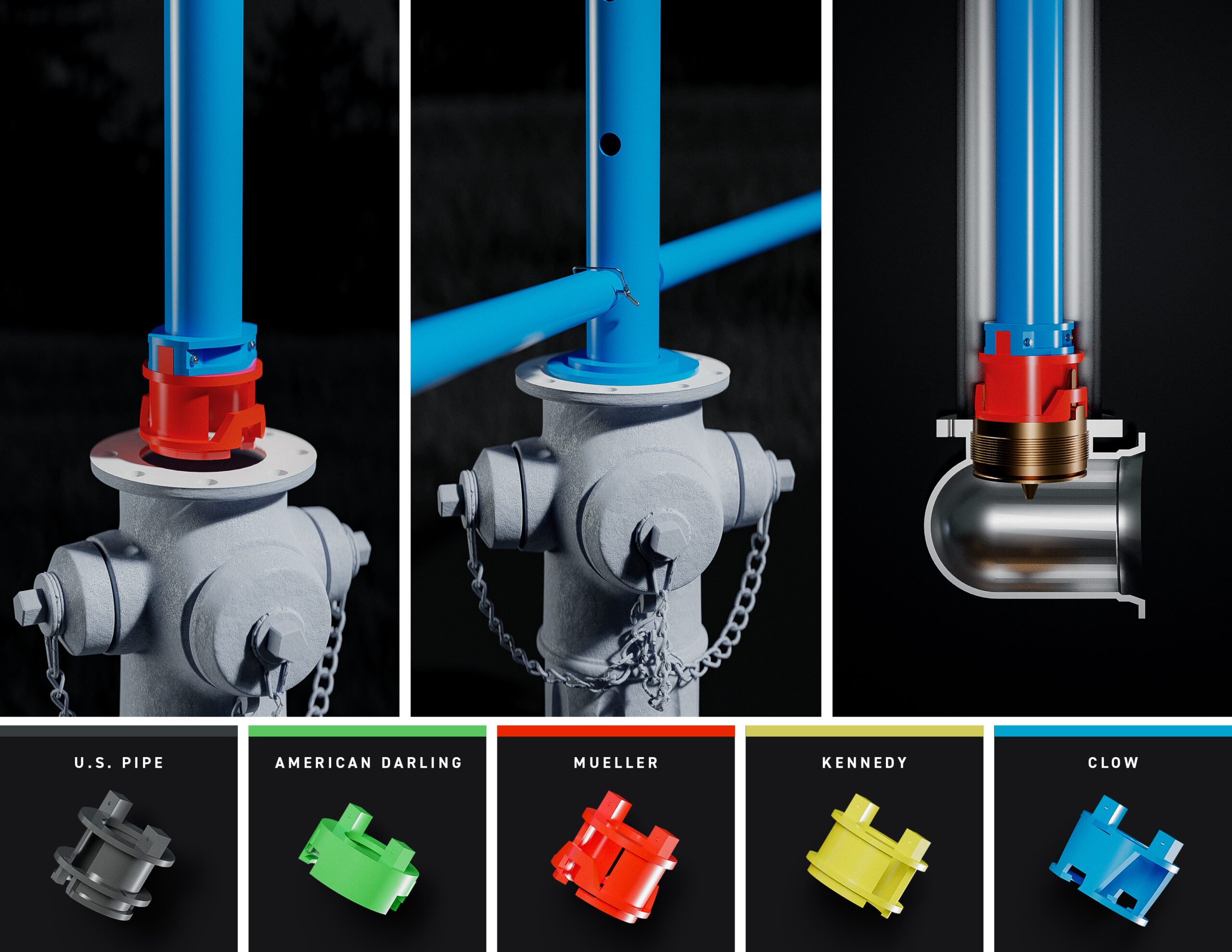

“It’s a universal tool in that there’s a socket designed for all the different fire hydrants we have within our system. That socket can be removed from the tool and interchanged depending on which fire hydrant needs repair,” Haldeman explained. “The extension tube that feeds down into the hydrant is made of lightweight material. Ours uses aluminum, which takes a lot of the stress and strain out of trying to use the tool.” (Pictured above, Universal Fire Hydrant Tool.)

The tool also reduces costs that could be passed along to customers. Previously, if a hydrant was challenging enough to break a tool during repair, digging it up to fix it cost about $8,000. With the tool, WSSC Water estimates its hydrant repairs cost $800, representing a potential 90% reduction.

“It provides a lot of leverage so that you can break free some of the more stubborn main valve assemblies, but you can actually take it apart and still store it in the truck,” Haldeman said.

Advertisement