Michigan airplane crash leads to unique water tank repair

October 19, 2022

AWWA Articles

Michigan airplane crash leads to unique water tank repair

The following is an excerpt from an article written by Erin Schmitt, media director for Pittsburg Tank & Tower Group, that was in the September 2022 issue of Opflow.

Eric Blackwell, tank maintenance foreman with Pittsburg Tank and Tower Group (PTTG), has been on the job for 20 years. He had never repaired a water tank struck by an airplane – until last fall.

Eric Blackwell, tank maintenance foreman with Pittsburg Tank and Tower Group (PTTG), has been on the job for 20 years. He had never repaired a water tank struck by an airplane – until last fall.

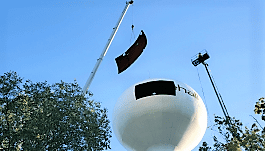

That’s when Kentucky-based PTTG was contracted to repair a steel column watersphere in Whitehall, Mich., following a deadly accident in which a pilot crashed his single-engine Cessna 150 into the tank on Sept. 9, 2019. The impact from the crash dented the tank, but there was no significant structural damage. (Pictured right, new panels lifted by crane to replace damaged metal.)

“I’ve made a lot of repairs on different tanks, but I’ve never replaced a section of a watersphere tank before,” Blackwell said.

“I’ve made a lot of repairs on different tanks, but I’ve never replaced a section of a watersphere tank before,” Blackwell said.

The cause of the plane crash, which resulted in the tragic death of the 79-year-old pilot, was undetermined. No other injuries occurred. Fortunately, the plane’s wreckage landed primarily within and on top of the boundary fence surrounding the water tower.

Town officials temporarily isolated the tank from the water system until it was inspected. Once it cleared safety protocols, the tank was put back into service until PTTG began repairs in September 2021.

PTTG, an AWWA member, constructed three new panels to repair damages on the City of Whitehall’s 500,000-gallon water tank. The brunt of the damage was to an 11-feet by 20-feet section of the city’s logo on the tank, specifically the “White” part of “Whitehall.”

As is typical of maintenance projects, there were a few delays, mostly due to weather. The tank was drained a day later than anticipated, and 30-miles-per-hour winds prevented the project from initially getting off the ground because it was unsafe to operate a crane in such conditions.

Once underway, the repair crew removed the damaged sections of steel using spider staging and working inside the tank. Once the new section was welded into place, an X-ray machine was used to check the integrity of the steel and the welds. Finishing touches included sandblasting the tank, repainting it, and returning the town’s name to the watersphere.

Advertisement